13 Years Manufacturer Tellerette Packing Ring Supply to Nairobi

13 Years Manufacturer Tellerette Packing Ring Supply to Nairobi Detail:

Material: PE, PP, RPP, PVC, CPVC and PVDF. Tellerette Packing Rings have features such as high void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific weight, high mass transfer efficiency, etc., and the application temperature in media ranges from 60℃ to 150 ℃.For these reasons, them are widely used in the packing towers in petroleum industry, chemical industry, alkali-Chloride industry, coal gas industry and environmental protection, etc.

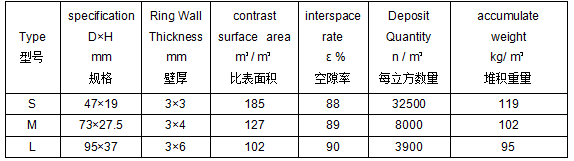

Technical Data Sheet

Product detail pictures:

Related Product Guide:

Comparison of O-Ring Materials

O-Ring Sizes for Industrial Applications

13 Years Manufacturer Tellerette Packing Ring Supply to Nairobi, The product will supply to all over the world, such as: , , ,