Well-designed Tellerette Packing Ring for Jamaica Factory

Well-designed Tellerette Packing Ring for Jamaica Factory Detail:

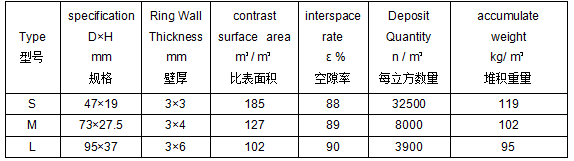

Material: PE, PP, RPP, PVC, CPVC and PVDF. Tellerette Packing Rings have features such as high void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific weight, high mass transfer efficiency, etc., and the application temperature in media ranges from 60℃ to 150 ℃.For these reasons, them are widely used in the packing towers in petroleum industry, chemical industry, alkali-Chloride industry, coal gas industry and environmental protection, etc.

Technical Data Sheet

Product detail pictures:

Related Product Guide:

Comparison of O-Ring Materials

A Look at the Molded Gasket

Well-designed Tellerette Packing Ring for Jamaica Factory, The product will supply to all over the world, such as: , , ,

Mechanical Systems’s Fully Automatic Pet Bottle Blowing Machine ,equipment is one high precision and speedy to make, bottles used for Water, Carbonated drinks, Hot fill juices, Pharmaceuticals & cosmetics , but also can used for different bottle shapes filling in one machine. With change over parts. Greatly improve the equipment usage

scope. Production capacity is from 2,000 bottles per hour to16,000 bottles per hour can be chosen by customers. Main-frame machine adopts frequency conversiontiming motor, convenient adjustment speed within throughput.

We are making 2 cavity, 4 cavity, 6 cavity Blow Machines fully auto as well as semi auto 2 cavity with auto drop feature as well.

C. Machine Features:

C.1. Stably performance with advanced PLC.

C.2. Conveying preforms automatically with conveyor.

C.3. Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself and revolute in the rails simultaneously in the infrared preheated.

C.4. High adjustability to enable the preheated to preheat preforms in shapes by adjusting the light tube and the length of the reflecting board in the preheating area, and eternal temperature in the preheated with an automatic thermostatic apparatus.

C.5. High safeties with security automatic-locking apparatus in each mechanical action, which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

C.6. No contamination and low noise with the air cylinder to drive the action instead of the oil pump.

C.7. Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

C.8. Strong clamping force with high pressure and double crank links to lock the mold.

C.9. Two ways of operating: automatic and manual.

C.10. Safe, reliable, and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

C.11. Low cost, high efficiency, easy operation, easy maintenance, etc, with automatic technological process.

C.12. Contamination is avoided for the bottle body.

C.13. Ideal effect of the chilling with the chilling system.

C.14. Easy installation and starting

C.15. Low rejection rate: less than 0.2 percent.

Mechanical Systems

302, HSIDC, Industrial Growth Centre, Saha

Ambala, Haryana (India)

Pin code: 133104

PH No.91-9466610761 ,9215477900, 8199944430, whatsapp/ Viber/ imo 0091-9466610761

Skype: mechsys2004

Email: mechsys2004@yahoo.com, mechsys@rediffmail.com

www.filling-machines.co.in, www.mechanicalsystems.in

About 9 hours of run in time on 5PSI.

Race spec full rebuild.

Engine mods only are:

HEAVILY Ported & Polished intake and exhaust runners (Flow tested and Port matched)

130lb Valve Springs

Replaced retainers, locks and seals

Valve seats cut

Full custom Cam (Total .562″ Intake, .593″ Exhaust)

Polished Alloy Valve Covers

1.7:1 Alloy Yella Terra Roller Rockers and Pushrods (very quite)

Rollmaster Double Row Timing Chain

OE-R Lifters

CUSTOM Cometic MLS Head Gaskets (Suited to 30PSI)

Acid Bathed and Ultrasonic cleaned block

Cryogenically hardened crank (by cryogen.com.au, very effective hardening process)

Fully balanced to 0.5 gram

ARP Head studs, ARP Main studs, ARP Big end bolts

ALL gaskets replaced with Factory standard or above

Balance shaft removed, dilled tapped oil feed

Cam, main and rod bearings (ALL Clevite, ALL TEFLON COATED)

JE Ceramic Coated and Forged Pistons

Forged Powdered Connecting Rods

Powerbond 5% overdrive harmonic balancer

Drilled main bearing oil feeds

Extensive Cooling and Oil Feed modifications

Machined oil pump cover

Casting smoothed oil pump and filter runners

High flow K&N oil filter

ALL Surfaces decked, Bored and Honed .020″ over

Cryogenically Hardened Block, Machine Rehoned after Hardening.

New Custom oil pump gears (hardened to increase longevity)

Custom Oil Pickup Tube

Fully Rebuilt and Recondition Supercharger

Custom Machined T6 Snout (YT lookalike) and Shaved to suit boost

Heavily ported/polished supercharger inlet and out

Inlet and outlet + port matched to heads LIM + Flow tested

Ported/Polished U-Bend

69.5mm Throttle Body

Custom externally vented PCV Breather system through supercharger