Factory Cheap price Serrated Gasket for Munich Manufacturers

Factory Cheap price Serrated Gasket for Munich Manufacturers Detail:

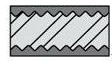

1.Structure

Serrated Gasket is made of machined flat metallic plate with waved or corrugated surface in 90 degree angle.

The Serrated Gasket with inner and outer rings or composite gasket attached with flexible graphite or Teflon sheet are available depending on the working location and requirement.

2.Characteristic

Serrated Gasket is an idea gasket used in low pre-tightening, the soft sealing surface avoid metal to metal touch, can be combined reliably and closely, protect flange not to be damaged. This kind of gasket is suitable to high pressure and high temperature location. Strong corrosion resistance, stable and reliable sealing function.

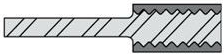

3.Gasket Typ

Basic Type With outer Ring

4. Working Environment

Working Temperature:~650℃

Working Pressure:6.4-16.0MP

Min. Pre-tightening:y=70MPa

Product detail pictures:

Related Product Guide:

What Is A PTFE Ring Gasket?

O-Ring Sizes for Industrial Applications

Factory Cheap price Serrated Gasket for Munich Manufacturers, The product will supply to all over the world, such as: , , ,

The Linuo knife gate is an economical, high performance knife gate valve used in pulp and paper, refining, wastewater, water treatment, mining, and chemical fiber industries.

It offers the following advanced features:

1) A super thin body design and compact construction, providing easy installation.

2) The seats movable design with a spring loaded O-ring serves to provide self-compensation to normal seat wear, resulting in long term service life. Excellent seal tightness is upheld throughout a prolonged life cycle. Metal seated, EPDM seated and PTFE seat designs are available for various process conditions.

3) The disk bottom provides a knife shaped design with strong cutting force, particularly applicable for pulp media. The disk guide is hard chromium plated after a perfect surface grinding allowing high abrasion and corrosion resistance.

4) PTFE guides insure tight gate to body contact with low friction and no damage to the gate. Small machined transitions at the port bottom prevent residue build-up and reduce downtime.

5) A variety of port designs are available for various process conditions, such as 3 port, triangle port, hexagonal port, and others.

6) The knife gate valve can be mounted with pneumatic and electric actuators control systems for used in automatic control systems in a variety of industries.