Trending Products Reinforced Flexible Graphite Gasket to Auckland Factory

Trending Products Reinforced Flexible Graphite Gasket to Auckland Factory Detail:

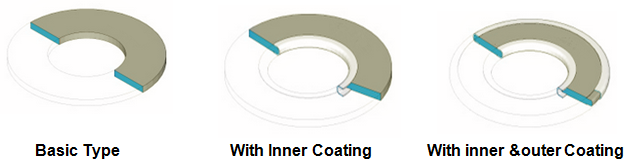

The reinforced flexible graphite composite gasket is composed of pressed metal sheet and flexible graphite grain after pressing and cutting.

1.Characteristic

Reinforced graphite gasket has perfect corrosion resistance, high &low temperature resistance, excellent elastic resilience, good strength. It can be cut into complex shape. Reinforced graphite gasket with inner &outer coating keeps all the excellent characteristics of itself, besides, it could be easily installed, disassembled, undamaged, meanwhile can prevent from medium corrosion, improve the pressure resistance.

2.Technical Data Sheet

|

Reinforced Material |

Pressure Resistance |

Temperature |

Elongation(%) |

Recovery(%) |

|

|

Oxidizing Environment |

Non-Oxidizing |

||||

|

CS Reinforce Sheet |

≥48 |

-10-450 |

-10-550 |

30-35 |

15-20 |

|

SS304,SS316 Reinforced Sheet |

≥48 |

-240-450 |

-200-600 |

30-35 |

15-30 |

|

SS304,SS316 Sheet |

≥48 |

-240-450 |

-200-600 |

30-40 |

10-15 |

|

Ss304, Mesh Sheet |

≥48 |

-240-450 |

-200-600 |

40-50 |

15-20 |

|

Reinforced Material |

Breathable (cm3/min) |

Leakage |

Seal Constant |

||

|

N2 m1/hr |

Bumming oil A |

“M” |

“Y” |

||

|

CS Reinforce Sheet |

<=0.8 |

30 |

<0.5 |

3.0 |

9000 |

|

SS304,SS316 Reinforced Sheet |

<=0.8 |

60 |

<0.5 |

2.5 |

4000 |

|

SS304,SS316 Sheet |

<=0.4 |

35 |

<0.5 |

2.0 |

900 |

|

SS304, Mesh Sheet |

≥1.0 |

70 |

<0.5 |

3.0 |

5000 |

Product detail pictures:

Related Product Guide:

O-Ring Sizes for Industrial Applications

Useful Tips For Installing The Teflon Envelope Gasket

Trending Products Reinforced Flexible Graphite Gasket to Auckland Factory, The product will supply to all over the world, such as: , , ,

Dirt is one of bearings worst enemies. Proper bearing prep and lubrication can help reduce downtime and maintenance costs. Learn how to avoid common mistakes and achieve optimal bearing performance.

Follow these five steps to ensure proper bearing lubrication:

1. Secure a clean work area and proper tools

2. Remove the bearing seal

3. Clean bearing with solvent and dry

4. Apply the lubricant – measuring the proper amount and ensuring even distribution

5. Replace the seals and shields

To learn more about high performance PFPE lubricants such as Krytox™ Performance Lubricants, visit:

https://www.chemours.com/Lubricants/en_US/applications/Bearings.html?utm_source=YouTube&utm_medium=youtube_howto_bearings&utm_term=lubes_for_bearings&utm_content=link_from_youtube_howto_bearings&utm_campaign=Krytox_HowTo