Quality Inspection for IMPAC Ring Export to US

Quality Inspection for IMPAC Ring Export to US Detail:

IMPAC RING is our new developed tower packing replacing Pall ring and other random tower packings. Compared with pall ring, IMPAC Ring has better compare surface area, and also can be working longer.

Material: Carbon Steel, SS304, SS304L, SS316, SS316L

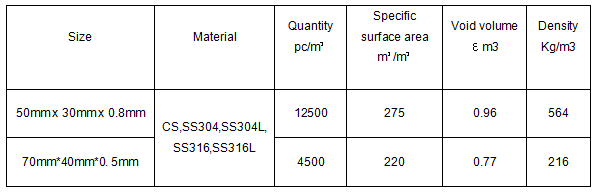

Technical Data Sheet

Product detail pictures:

Related Product Guide:

Useful Tips For Installing The Teflon Envelope Gasket

What Is A PTFE Ring Gasket?

Quality Inspection for IMPAC Ring Export to US, The product will supply to all over the world, such as: , , ,