China Manufacturer for Pall Ring Wholesale to United Kingdom

China Manufacturer for Pall Ring Wholesale to United Kingdom Detail:

Pall Ring has features of low pressure drop, great flux, high efficiency.

Material: Stainless steel, carbon steel, aluminum, bronze, 304L, 316L, and other alloy, carbon seep aluminium.Strengthen polypropylene, strengthen nylon6, strengthen nylon66, strengthening PBT can also be requested by user.

Application: Used in all kind of separation, absorb, dis-absorb plants, constant decompress plants, compounding ammonia plant, decarbonization plant, desulfuration plant,separation of ethylbenzene, separation of isooctane/ methylbenzene.

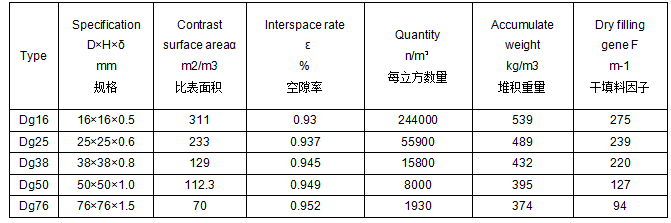

Technical Data Sheet

Product detail pictures:

Related Product Guide:

Useful Tips For Installing The Teflon Envelope Gasket

A Look at the Molded Gasket

China Manufacturer for Pall Ring Wholesale to United Kingdom, The product will supply to all over the world, such as: , , ,