New Delivery for IMPAC Ring for Ghana Factory

New Delivery for IMPAC Ring for Ghana Factory Detail:

IMPAC RING is our new developed tower packing replacing Pall ring and other random tower packings. Compared with pall ring, IMPAC Ring has better compare surface area, and also can be working longer.

Material: Carbon Steel, SS304, SS304L, SS316, SS316L

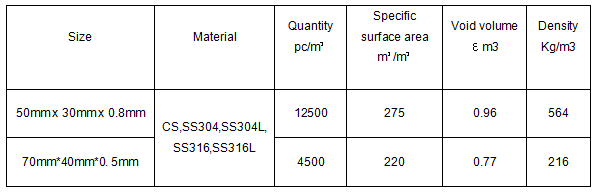

Technical Data Sheet

Product detail pictures:

Related Product Guide:

Comparison of O-Ring Materials

A Look at the Molded Gasket

New Delivery for IMPAC Ring for Ghana Factory, The product will supply to all over the world, such as: , , ,

After i got done siliconing and painting my box, I figured I’ll make a ‘How to’ video on sealing the gap between the subwoofer and the box. My total cost out of pocket to just seal the gap was less $15 after tax. But prices may vary depending on the hardware store that’s nearest to you.

There was a couple of things I forgot to mention in the video. When you you apply the weather stripping, make sure the surface area is clean and free of any dust. Second, and most important, once you have the mounting hole of the sub lined up with mounting holes, DON’T put a lot of presseure when tightening the screws. Put to much pressure and you’ll push the t-nut out of it’s place. Happened to me twice, hahaha!

So, yeah, just put enough pressure to let the screw tighten. Then once it’s tight, you can torque down the screw tight enough so it won’t come loose.

Thanks for watching my vid, and please rate.

mastagoof

https://www.sealmaster.com

At Seal Master we take pride in our products and stand by their quality. Each Seal Master product is inspected a minimum of two times prior to shipment by two separate Seal Master Quality inspectors. During this process inspectors are looking for obvious cosmetic defects but are also trained to be aware of other problems that may occur during operation. Below are examples of some inspection processes that take place prior to shipment.