Good Quality for Muti-Surface Hollow Ball to Leicester Importers

Good Quality for Muti-Surface Hollow Ball to Leicester Importers Detail:

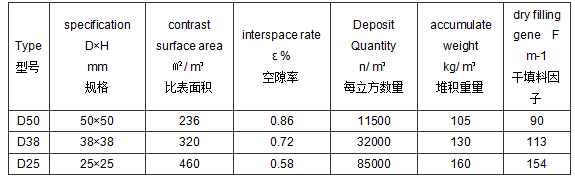

Material: Polypropylene, Polyethylene, PVC, or can be requested by user.

Application: Used in gas absorb, disabsorb, washer, demist equipment

Product detail pictures:

Related Product Guide:

What Is A PTFE Ring Gasket?

Comparison of O-Ring Materials

Good Quality for Muti-Surface Hollow Ball to Leicester Importers, The product will supply to all over the world, such as: , , ,

Following Alu rolling mill for sale

Used Aluminium Foil Mill

- Manufacturer Achenbach, Germany

- Manufacture year 1986

- Material Aluminium foil

- Entry thickness Max. 0.4 mm

- Exit thickness Min. 2*0.006 mm

- Strip width Max. 1,450 mm

Min. 800 mm

- Coil weight Max. 6,300 kg

- Spool dimension Dia. 400*1,700 mm

Dia. 279*1,245 mm

- Exit coil dia. Dia. 400/1,485 mm

- Roiling speed 0 – 800/1,500 m/min.

- Roiling force Max. 5,000 kN

- Back-up roll bearing Cylindrical roller bearing and deep groove ball bearing

- Work roll bearing Cylindrical roller bearing and taper roller bearing

- Main motor 850 kw

- Decoiler motor 85 kw * 2 sets

- Double decoiler motor 85 kw

- Recoiler motor 85 kw * 3 sets

- Thickness gauge FAG (Isotope)

- Automatic flatness control BBC (BFI)

- Drive system DC drive (BBC)

- PLC DP 800 (BBC)

- Electric power source 440 V 3 Phase 60 Hz

The Hosokawa Micron Powder Characteristics Tester PT-X makes use of state of the art features to identify the characteristics of a wide range of powdered materials. The instrument is capable of determining 11 different characteristics.

Compressibility

Compressibility is the percentage amount of volume loss a substance will sustain when put under pressure. Essentially, it is how much an object can be crushed without being destroyed.

Determining the Compressibility

The compressibility of a material is determined through two tests: the aerated density test, and the tapped density test. The difference between the results of the aerated density test and the tapped density test is the substance’s compressibility. This video explains how the Hosokawa Micron Characteristics Tester PT-X can be used to determine the compressibility of a granulator material.