Trending Products Reinforced Flexible Graphite Gasket to Auckland Factory

Trending Products Reinforced Flexible Graphite Gasket to Auckland Factory Detail:

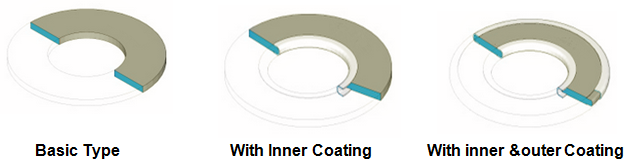

The reinforced flexible graphite composite gasket is composed of pressed metal sheet and flexible graphite grain after pressing and cutting.

1.Characteristic

Reinforced graphite gasket has perfect corrosion resistance, high &low temperature resistance, excellent elastic resilience, good strength. It can be cut into complex shape. Reinforced graphite gasket with inner &outer coating keeps all the excellent characteristics of itself, besides, it could be easily installed, disassembled, undamaged, meanwhile can prevent from medium corrosion, improve the pressure resistance.

2.Technical Data Sheet

|

Reinforced Material |

Pressure Resistance |

Temperature |

Elongation(%) |

Recovery(%) |

|

|

Oxidizing Environment |

Non-Oxidizing |

||||

|

CS Reinforce Sheet |

≥48 |

-10-450 |

-10-550 |

30-35 |

15-20 |

|

SS304,SS316 Reinforced Sheet |

≥48 |

-240-450 |

-200-600 |

30-35 |

15-30 |

|

SS304,SS316 Sheet |

≥48 |

-240-450 |

-200-600 |

30-40 |

10-15 |

|

Ss304, Mesh Sheet |

≥48 |

-240-450 |

-200-600 |

40-50 |

15-20 |

|

Reinforced Material |

Breathable (cm3/min) |

Leakage |

Seal Constant |

||

|

N2 m1/hr |

Bumming oil A |

“M” |

“Y” |

||

|

CS Reinforce Sheet |

<=0.8 |

30 |

<0.5 |

3.0 |

9000 |

|

SS304,SS316 Reinforced Sheet |

<=0.8 |

60 |

<0.5 |

2.5 |

4000 |

|

SS304,SS316 Sheet |

<=0.4 |

35 |

<0.5 |

2.0 |

900 |

|

SS304, Mesh Sheet |

≥1.0 |

70 |

<0.5 |

3.0 |

5000 |

Product detail pictures:

Related Product Guide:

A Look at the Molded Gasket

Useful Tips For Installing The Teflon Envelope Gasket

Trending Products Reinforced Flexible Graphite Gasket to Auckland Factory, The product will supply to all over the world, such as: , , ,

FOAMBAG™ is a low-cost flow stopping system based on the use of expanding resin foam. The effective yet simple technique works on all types of pipe material including cast iron, steel and PE. Extremely versatile, it can be used on vertical or tapering pipes, bends and non-standard diameters. Although developed for flow stopping natural gas pipes, FOAMBAG™ can also be used to seal pipes carrying other gases and fluids. The technique works by inserting a semi-porous bag into the pipe to hold the foam in place as it expands. At full expansion, some of the foam seeps through the semi-porous material to adhere to the pipe wall.

For more information; www.pipeserv.com