Factory Cheap price Serrated Gasket for Munich Manufacturers

Factory Cheap price Serrated Gasket for Munich Manufacturers Detail:

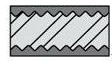

1.Structure

Serrated Gasket is made of machined flat metallic plate with waved or corrugated surface in 90 degree angle.

The Serrated Gasket with inner and outer rings or composite gasket attached with flexible graphite or Teflon sheet are available depending on the working location and requirement.

2.Characteristic

Serrated Gasket is an idea gasket used in low pre-tightening, the soft sealing surface avoid metal to metal touch, can be combined reliably and closely, protect flange not to be damaged. This kind of gasket is suitable to high pressure and high temperature location. Strong corrosion resistance, stable and reliable sealing function.

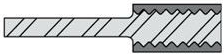

3.Gasket Typ

Basic Type With outer Ring

4. Working Environment

Working Temperature:~650℃

Working Pressure:6.4-16.0MP

Min. Pre-tightening:y=70MPa

Product detail pictures:

Related Product Guide:

A Look at the Molded Gasket

Comparison of O-Ring Materials

Factory Cheap price Serrated Gasket for Munich Manufacturers, The product will supply to all over the world, such as: , , ,

Vetaphone and Coating Plasma Industrie demonstrates the EASI-Plasma system for surface treatment of films and foils.

Vetaphone’s EASI-Plasma system works on the same principles as a Corona system, but by replacing the oxygen with gases or monomers, the EASI-Plasma can create new and innovative abilities on the film surface. The EASI-Plasma system does this with a significantly lower amount of consumables than any other solution on the market.

Benefits of EASI-Plasma

• Higher and longer lasting dyne values

• Replace your primer or coating unit with a cheaper solution

• Nano-coating thickness only 5-50 nm

• Anti-fog

• Hydrophilic or Hydrophobic surface

• A large variety of other abilities

EASI-Plasma provides a wide range of benefits for the coating and converting processes; such as nano-coating, anti-fog properties, low surface ageing and higher dyne levels.

EASI-Plasma reduces production costs by eliminating the need to use expensive primer, so the cost per m2 is reduced significantly. As the layer of primer is not needed, it is possible to produce much thinner film.

Similar advantages are present, when using the EASI-Plasma for nano-coating. By making the nano-coated layer only 5-50 nm thick, the EASI-Plasma brings down the cost per m2 and creates possibilities to produce new innovative thinner films.

All in all there is a great potential for saving resources and creating new surface abilities by employing EASI-Plasma.

A simple, effective, and most importantly SAFE way to heat your hot water with a woodstove. The natural laws of convection and thermosyphon do all of the work.

I would ask that all interested in this concept to take the time to read all of the great comments below before contributing, there is much to be shared and learned!

Sorry, the website/business has been temporarily suspended in order to start a new pv solar business, www.nh.solar