Best quality and factory Tellerette Packing Ring for Costa rica Manufacturers

Best quality and factory Tellerette Packing Ring for Costa rica Manufacturers Detail:

Material: PE, PP, RPP, PVC, CPVC and PVDF. Tellerette Packing Rings have features such as high void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific weight, high mass transfer efficiency, etc., and the application temperature in media ranges from 60℃ to 150 ℃.For these reasons, them are widely used in the packing towers in petroleum industry, chemical industry, alkali-Chloride industry, coal gas industry and environmental protection, etc.

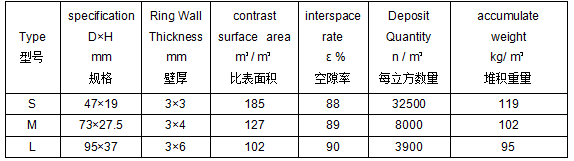

Technical Data Sheet

Product detail pictures:

Related Product Guide:

Comparison of O-Ring Materials

O-Ring Sizes for Industrial Applications

Best quality and factory Tellerette Packing Ring for Costa rica Manufacturers, The product will supply to all over the world, such as: , , ,

James Belushi is Jimmy Dworski, a happy-go-lucky convict who breaks out of prison and finally gets a life … somebody else’s! When Dworski finds the daily planner book that literally runs the life of ultra-organized executive Spencer Barnes (Charles Grodin), all hell breaks loose! With newfound cash, credit cards, and the keys to a Malibu mansion, the imposter Dworski embarks on an all-expense-paid trip to “Easy Street” while posing as the high-powered Barnes. Meanwhile, Spencer’s life is turned upside down as he hunts through the jungles of Los Angeles for his beloved book! When these oddball opposites finally meet, it’s a comedic collision you won’t soon forget!