OEM/ODM Supplier for Tellerette Packing Ring for Uganda Manufacturers

OEM/ODM Supplier for Tellerette Packing Ring for Uganda Manufacturers Detail:

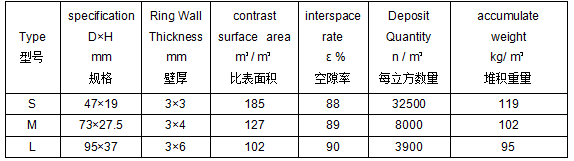

Material: PE, PP, RPP, PVC, CPVC and PVDF. Tellerette Packing Rings have features such as high void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific weight, high mass transfer efficiency, etc., and the application temperature in media ranges from 60℃ to 150 ℃.For these reasons, them are widely used in the packing towers in petroleum industry, chemical industry, alkali-Chloride industry, coal gas industry and environmental protection, etc.

Technical Data Sheet

Product detail pictures:

Related Product Guide:

Comparison of O-Ring Materials

A Look at the Molded Gasket

OEM/ODM Supplier for Tellerette Packing Ring for Uganda Manufacturers, The product will supply to all over the world, such as: , , ,

Shanghai Kuko Packing Machinery Co., Ltd

Add : No.658-E, Qiangye Rd, Songjiang District, Shanghai, China

Tel : +86-(0)21-5226 5219/ 6974 6020 Fax : +86-(0)21-6221 9769

E-mail: info@goodpacking.com.cn https://en.goodpacking.com.cn

Suitable shrink film: PE, POF, PVC;

Application: Hardware, daily used products, pharmaceutical etc;

The sealing blade adopts continuous heating system;

Waste materials treatment system: Coiling method and speed is 16.2m/min.;

Packaging style: L type sealing makes three side sealing packing;

The blade retracts while cutting objects;

The advanced technology of cold cutting reduces the consumption of electrical power;

Conveyors adopt high frequency step less speed regulation technology.

Hot air cycling system in the shrinking chamber makes products shrink more The tunnel conveyor uses frequency inverter to adjust the speed which is much better than the speed controller;

There is roller type conveyor & Teflon mesh conveyor for your option.

Model SF-400LA L Sealer SF-4525 Shrink Tunnel

Power Supply 220V 50Hz 1phase

220V 60Hz 3phase 1.5kw 380V 50Hz 3phase

220V 60Hz 3phase 8kw

Tunnel Size(L×W×H) 1200×450×250mm

Shrink Film PE, POF, PVC POF, PVC

Max. Packing Size L500 x W300 x H125mm

Packing Speed 18~25pcs/min. 2000~3000pcs/hour

Machine Size(L×W×H) 2100×940×1600mm 1800×850×1550mm

Packaging Size(L×W×H) 2150×990×1750mm 1850×900×1700mm

Net/Gross Weight 300kgs/340kgs 260kgs/300kgs

Sealing Part

Item Name Brand Remarks

Sensor Banner From U.S.A

Solid Relay Aole From Taiwan

Cylinder AIRTAC From Taiwan

Solenoid Valve AIRTAC From Taiwan

Reducing Motor GPG From Taiwan

Film Motor Surfon From Taiwan

All Switches Siemens From Germany

Heating Elements Home-made From China

Cutter Home-made From China

Shrink Tunnel

Item Name Brand Remarks

Solid Relay Aole From Taiwan

Reducing Motor GPG From Taiwan

Recycling Motor Liangchi From Taiwan

Temperature Controller Autonics From Korea

Frequency Inverter Schneider From France

All Switches Siemens From Germany

Insulation Aluminum Silicate 5cm thickness

Intermediate Relay Siemens From Germany