Free sample for Muti-Surface Hollow Ball for Moscow Importers

Free sample for Muti-Surface Hollow Ball for Moscow Importers Detail:

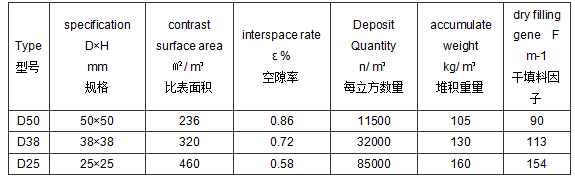

Material: Polypropylene, Polyethylene, PVC, or can be requested by user.

Application: Used in gas absorb, disabsorb, washer, demist equipment

Product detail pictures:

Related Product Guide:

Useful Tips For Installing The Teflon Envelope Gasket

What Is A PTFE Ring Gasket?

Free sample for Muti-Surface Hollow Ball for Moscow Importers, The product will supply to all over the world, such as: , , ,