Professional High Quality Muti-Surface Hollow Ball for Belarus Manufacturers

Professional High Quality Muti-Surface Hollow Ball for Belarus Manufacturers Detail:

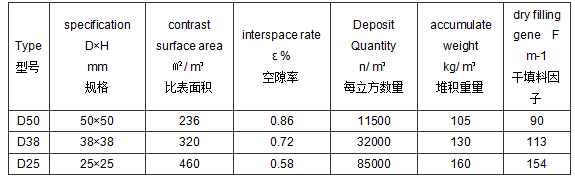

Material: Polypropylene, Polyethylene, PVC, or can be requested by user.

Application: Used in gas absorb, disabsorb, washer, demist equipment

Product detail pictures:

Related Product Guide:

O-Ring Sizes for Industrial Applications

Useful Tips For Installing The Teflon Envelope Gasket

Professional High Quality Muti-Surface Hollow Ball for Belarus Manufacturers, The product will supply to all over the world, such as: , , ,

www.trumarkindia.com

info@trumarkindia.com

whatsapp/ viber/hike +91-9870789174

skype: trumarkpharma

Automatic web sealer with shrink tunnel; machine is suitable to shrink wrap & pack bundle or bunch of bottles in a preset matrix size(row & columns),

Principle of Operation – Automatic Sleeve Wrapper The Sleeve Wrapper with sealing bar uses two rolls of single wound shrink film. One film roll is kept on the roll holder at top and another roll kept at the bottom. Once the film from both the rolls is sealed to make a joint, it forms a curtain through which the products are pushed through and the film is sealed again at the back side of the products. This forms a tube of film (open at two ends) around the product(s). The products are then transferred to the shrink tunnel for final shrinking.

Operation – Automatic Sleeve Wrapper The sealing system consists of a Special sealing system suitable for P.E.films. The infeed table of the sealing unit receives the product and and are pushed to the outfeed area of sealing unit through the film curtain. Once the cartons reach the sealing area, the top hold down will be actuated to hold the carton and sealing arm is actuated. The sealing arm makes the seal and top hold down and sealing bar retracts and this completes the sealing operation. Once the sealing arm retracts the next product can be pushed to sealing area. The complete sequence including unwinding motors is controlled through PLC.

Standard Machine Features:

• Heavy Duty and robust frame in MS painted structure

• Emergency stop

• Teflon Coated Special Structure Hot Knife Sealing System

• L/H or R/H side infeed customized as per customer’s requirement

Please let us know for any , Bundling and Shrink Wrapping Machine, Collating and Shrink Wrapping Machine, Automatic Shrink Wrapping Machine bottle shrink wrapping machine

shrink wrapping machine cost , shrink wrapping machine video,

pallet shrink wrapping machine,

carton shrink wrapping machine,

shrink wrapping machine dealer ,

automatic shrink wrapping machine ,

shrink wrapping machine exporter ,

shrink wrapping machine manufacturer

machine in exporter, supplier in USA, Canada, Virginia , Alabama, Alaska, Arizona, Arkansas, California, Colorado, Connecticut, Delaware, Florida, Georgia, Hawaii, Idaho, Illinois, Indiana, Iowa, Kansas, Kentucky, Louisiana, Maine, Maryland, Massachusetts, Michigan, Minnesota, Mississippi, Missouri, Montana, Nebraska, Nevada, New Hampshire, New Jersey, New Mexico, New York, North Carolina, North Dakota, Ohio, Oklahoma, Oregon, Pennsylvania, Rhode Island, South Carolina, South Dakota,Tennessee, Texas, Utah, Vermont, Virginia, Washington, West Virginia, Wisconsin ,Wyoming,

Canada, Mexico, United States, Argentina, Bolivia, Brazil , Chile, Colombia, Ecuador, French Guiana, Guyana, Paraguay, Peru, Suriname, Uruguay, Venezuela, Belize,Costa Rica, El Salvador, Guatemala, Honduras, Nicaragua, Panama, Anguilla, Antigua and Barbuda, Aruba, Bahamas, Barbados, Bermuda, British Virgin Islands, Cayman Islands,

Cuba, Dominica, Dominican Republic, Grenada, Guadeloupe, Haiti, Jamaica, Martinique, Montserrat, Netherlands Antilles, Puerto Rico, Saint Kitts and Nevis, Saint Lucia, Saint Vincent and the Grenadines, Trinidad and Tobago, US Virgin Islands

France, Poland, Bulgaria, Saudi Arabia, Ecuador, Peru, South Africa, Egypt, Indonesia, UAE, Vietnam, Pakistan, Uganda, Philippines, Greece, Columbia, Malaysia, Nigeria, Ethiopia, Lebanon, Kenya, Kuwait, Sri Lanka, Ghana, Nepal, Ukraine, Bangladesh, Australia, Switzerland, Sudan, Russia, Yemen, Iran, Morocco, Malawi, Thailand, Tanzania, Canada, Belarus ,USA ,Cyprus ,UAE ,Republic of Congo ,Canada ,Russia ,South Africa ,Crotia ,Nepal ,OMAN ,UKRAINE ,China ,Bhutan ,Ghana ,Yugoslavia ,Nigeria ,Netherlands ,Vietnam ,Thailand ,Kenya ,Iran ,Malaysia ,Bangladesh ,Pakistan, U.A.E , SAUDI ARABIA , Monrovia , Phillipines , Spain ,Liberia , Iran ,U.S.A, Canada, Germany, Italy, Jordan, Syria, Turkey, Kuwait, Iran, Algeria, Argentina, Bangladesh, Bangkok, Indonesia, Malaysia, Vietnam, Nigeria, Ghana, Malawi, Egypt, Ukraine, Nepal, Srilanka, Bangladesh, Tibet Lusaka, Egypt, England, UAE, Bahrain, Vietnam, Iran, Poland, Tanzania, Malaysia, Nigeria, Sudan, U.K., Italy, Thailand, Span, Kenya, Lebanon, Kingdom of Saudi Arabia, Sudan, Botswana, Iraq, Thailand, Span, Mauritius, Ethopia, Congo, Zambia, Namibia, Mozambique, Uganda, Yemen, Somaliya, Oman, Jordan, Turkey, Labia, Morocco, France, Germany, Ukraine, Turkey, Greece, Kazakhstan, Russia, Uzbekistan, Malaysia, Thailand,Singapore, Philipines, Indonesia, Australlia, New Zealand, kerala, trichy, banglore, chennai, delhi, jammu, kolkata, bhubneshwar, baddi, himachal pradesh, rajasthan, pune, nashik, dhule, solan, kanpur, coimbatore, satna, nagpur, thane, wada, jaipur, udaipur, ahemdabad, ludhiyana, hyderabad, tamilnadu, kolkata