Best Price on Reinforced Flexible Graphite Gasket Export to Spain

Best Price on Reinforced Flexible Graphite Gasket Export to Spain Detail:

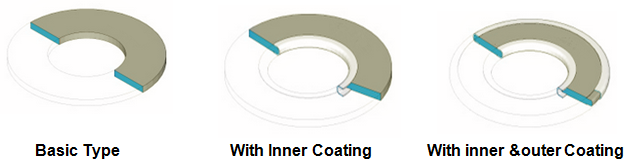

The reinforced flexible graphite composite gasket is composed of pressed metal sheet and flexible graphite grain after pressing and cutting.

1.Characteristic

Reinforced graphite gasket has perfect corrosion resistance, high &low temperature resistance, excellent elastic resilience, good strength. It can be cut into complex shape. Reinforced graphite gasket with inner &outer coating keeps all the excellent characteristics of itself, besides, it could be easily installed, disassembled, undamaged, meanwhile can prevent from medium corrosion, improve the pressure resistance.

2.Technical Data Sheet

|

Reinforced Material |

Pressure Resistance |

Temperature |

Elongation(%) |

Recovery(%) |

|

|

Oxidizing Environment |

Non-Oxidizing |

||||

|

CS Reinforce Sheet |

≥48 |

-10-450 |

-10-550 |

30-35 |

15-20 |

|

SS304,SS316 Reinforced Sheet |

≥48 |

-240-450 |

-200-600 |

30-35 |

15-30 |

|

SS304,SS316 Sheet |

≥48 |

-240-450 |

-200-600 |

30-40 |

10-15 |

|

Ss304, Mesh Sheet |

≥48 |

-240-450 |

-200-600 |

40-50 |

15-20 |

|

Reinforced Material |

Breathable (cm3/min) |

Leakage |

Seal Constant |

||

|

N2 m1/hr |

Bumming oil A |

“M” |

“Y” |

||

|

CS Reinforce Sheet |

<=0.8 |

30 |

<0.5 |

3.0 |

9000 |

|

SS304,SS316 Reinforced Sheet |

<=0.8 |

60 |

<0.5 |

2.5 |

4000 |

|

SS304,SS316 Sheet |

<=0.4 |

35 |

<0.5 |

2.0 |

900 |

|

SS304, Mesh Sheet |

≥1.0 |

70 |

<0.5 |

3.0 |

5000 |

Product detail pictures:

Related Product Guide:

Comparison of O-Ring Materials

O-Ring Sizes for Industrial Applications

Best Price on Reinforced Flexible Graphite Gasket Export to Spain, The product will supply to all over the world, such as: , , ,

Applications

1. The stick bag is a popular international packaging shape. It is also called pre-shaped bags, expansion bags. It is a novel form of packaging, diverse modeling, reliable measurement, seal firm, easy to use, and low cost packaging materials, etc.

2. It is widely used in dairy products such as milk, yogurt, lactic acid drinks, Japanese tofu, soy sauce, cooking oil, drinks, mineral water, cleaning supplies, alcohol, etc.

Features

1. It adopts 304 stainless steel, and PLC system control.

2. Chinese and English man-machine interface, Visualization operation

3. It adopts pressurized filling in airless. And it can avoid secondary pollution.

4. It is automatic entire process by PLC control system, such as filling, sealing, dropping bags, etc.

5. Unique filling nozzles design, no leaking filling.

6. Unique sealing part, seal firm bag and avoid squeeze hand.

Main configuration

1. SUS304 stainless steel

2. WEINVIEW touch screen, MITSUBISHI PLC system, Other CHINT electrical equipment.

3. AIRTAC pneumatic components

4. Food – grade silicone tube

Selections help for plastic bag machine

1. Filling material viscosity

Standards: adopting sanitary centrifugal pump, mainly applied to low concentration liquid.

Viscous-type: adopting sanitary pneumatic forced pump, mainly applied to large viscosity liquid.

2. Bag material

Standards: BOPP laminated LDPE.

Special: PE or Nylon. It need add Teflon material in the sealed parts.

Packing rate 2000-3500 bags/hr

Filling nozzles 8

Workstation 2

Bag material BOPP laminated LDPE, various shapes pre-shaped bags

Film thickness >0.18mm

Filling volume ≤500ml (Custom)

Filling accuracy ±2%

Power input 220V 50Hz / 220V 60Hz / 110V 60Hz

Power 0.8-1.6 Kw

Air Pressure 0.6-0.8 Mpa

Air Consumption 0.25-0.50 m3/min

Net weight ≈80 kg

Overall dimension 1100×700×1050 mm3(L×W×H)