OEM/ODM Factory for Reinforced Flexible Graphite Gasket to Anguilla Factories

OEM/ODM Factory for Reinforced Flexible Graphite Gasket to Anguilla Factories Detail:

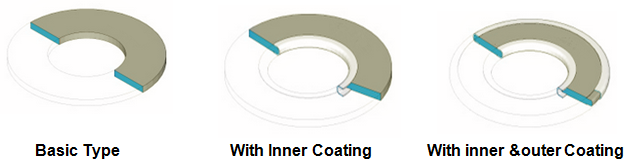

The reinforced flexible graphite composite gasket is composed of pressed metal sheet and flexible graphite grain after pressing and cutting.

1.Characteristic

Reinforced graphite gasket has perfect corrosion resistance, high &low temperature resistance, excellent elastic resilience, good strength. It can be cut into complex shape. Reinforced graphite gasket with inner &outer coating keeps all the excellent characteristics of itself, besides, it could be easily installed, disassembled, undamaged, meanwhile can prevent from medium corrosion, improve the pressure resistance.

2.Technical Data Sheet

|

Reinforced Material |

Pressure Resistance |

Temperature |

Elongation(%) |

Recovery(%) |

|

|

Oxidizing Environment |

Non-Oxidizing |

||||

|

CS Reinforce Sheet |

≥48 |

-10-450 |

-10-550 |

30-35 |

15-20 |

|

SS304,SS316 Reinforced Sheet |

≥48 |

-240-450 |

-200-600 |

30-35 |

15-30 |

|

SS304,SS316 Sheet |

≥48 |

-240-450 |

-200-600 |

30-40 |

10-15 |

|

Ss304, Mesh Sheet |

≥48 |

-240-450 |

-200-600 |

40-50 |

15-20 |

|

Reinforced Material |

Breathable (cm3/min) |

Leakage |

Seal Constant |

||

|

N2 m1/hr |

Bumming oil A |

“M” |

“Y” |

||

|

CS Reinforce Sheet |

<=0.8 |

30 |

<0.5 |

3.0 |

9000 |

|

SS304,SS316 Reinforced Sheet |

<=0.8 |

60 |

<0.5 |

2.5 |

4000 |

|

SS304,SS316 Sheet |

<=0.4 |

35 |

<0.5 |

2.0 |

900 |

|

SS304, Mesh Sheet |

≥1.0 |

70 |

<0.5 |

3.0 |

5000 |

Product detail pictures:

Related Product Guide:

Comparison of O-Ring Materials

What Is A PTFE Ring Gasket?

OEM/ODM Factory for Reinforced Flexible Graphite Gasket to Anguilla Factories, The product will supply to all over the world, such as: , , ,

Thanks all the clients!

Our bonded seal has passed the UKAS ISO 9001certification,

and the producing processes are according to the rule of Europe quality standard.

Europe high quality,China factory price.

Should you have any questions,

please don’t hesitate to contact us.

Free samples for your testing.

Best Regards

Wang YiJie

Ren County LongHai Hydraulic Sealing Factory

Add:xinxing zhuang,tiankou town,Ren county,Xingtai City,China

www.bonded-seal.com

info@bonded-seal.com

europe@bonded-seal.com

skype:bonded-seal

whatsapp:+8615933389288

Twitter:https://www.twitter.com/Bonded_Seal

Facebook:https://www.facebook.com/bonded.seal

YouTuBe:https://youtu.be/Khve11REQxA