Quality Inspection for Reinforced Flexible Graphite Gasket for Greek Factories

Quality Inspection for Reinforced Flexible Graphite Gasket for Greek Factories Detail:

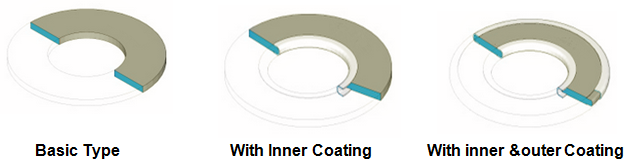

The reinforced flexible graphite composite gasket is composed of pressed metal sheet and flexible graphite grain after pressing and cutting.

1.Characteristic

Reinforced graphite gasket has perfect corrosion resistance, high &low temperature resistance, excellent elastic resilience, good strength. It can be cut into complex shape. Reinforced graphite gasket with inner &outer coating keeps all the excellent characteristics of itself, besides, it could be easily installed, disassembled, undamaged, meanwhile can prevent from medium corrosion, improve the pressure resistance.

2.Technical Data Sheet

|

Reinforced Material |

Pressure Resistance |

Temperature |

Elongation(%) |

Recovery(%) |

|

|

Oxidizing Environment |

Non-Oxidizing |

||||

|

CS Reinforce Sheet |

≥48 |

-10-450 |

-10-550 |

30-35 |

15-20 |

|

SS304,SS316 Reinforced Sheet |

≥48 |

-240-450 |

-200-600 |

30-35 |

15-30 |

|

SS304,SS316 Sheet |

≥48 |

-240-450 |

-200-600 |

30-40 |

10-15 |

|

Ss304, Mesh Sheet |

≥48 |

-240-450 |

-200-600 |

40-50 |

15-20 |

|

Reinforced Material |

Breathable (cm3/min) |

Leakage |

Seal Constant |

||

|

N2 m1/hr |

Bumming oil A |

“M” |

“Y” |

||

|

CS Reinforce Sheet |

<=0.8 |

30 |

<0.5 |

3.0 |

9000 |

|

SS304,SS316 Reinforced Sheet |

<=0.8 |

60 |

<0.5 |

2.5 |

4000 |

|

SS304,SS316 Sheet |

<=0.4 |

35 |

<0.5 |

2.0 |

900 |

|

SS304, Mesh Sheet |

≥1.0 |

70 |

<0.5 |

3.0 |

5000 |

Product detail pictures:

Related Product Guide:

A Look at the Molded Gasket

What Is A PTFE Ring Gasket?

Quality Inspection for Reinforced Flexible Graphite Gasket for Greek Factories, The product will supply to all over the world, such as: , , ,

The SM100 range is a popular choice for narrow width slitting of a wide range of films, laminates, label stock and paper.

Main features:-

•Standard models for 350mm and 800mm web width

•Rotary shear, razor and/or crush cut slitting

•Variable speed DC or AC drives with PLC control

•Duplex or simplex centre driven rewinds

•610mm, 800mm or 1000mm diameter unwind and rewind reels

•Lock bar and/or differential rewind shafts

•Automatic unwind and rewind control

Options include:-

•Anti static control

•Push button pneumatic knife engagement

•Trim/scrap removal

•Digital/automatic knife positioning

•Reversing rewind drive

•Unwind and rewind reel loading equipment

•Splicing table with pneumatic clamps

•Adjustable pneumatic lay-on rollers

Benefits:

•Eliminates shaft handling

•Faster reel changes

•Easier thread up

•Reduced down time

•Increased productivity

•High speed

•Accurate

•Cost effective