New Fashion Design for Reinforced Flexible Graphite Gasket Wholesale to Iran

New Fashion Design for Reinforced Flexible Graphite Gasket Wholesale to Iran Detail:

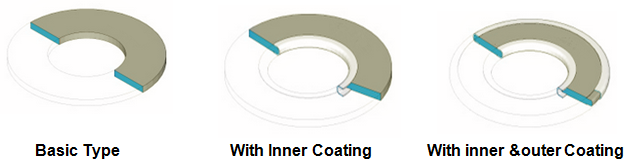

The reinforced flexible graphite composite gasket is composed of pressed metal sheet and flexible graphite grain after pressing and cutting.

1.Characteristic

Reinforced graphite gasket has perfect corrosion resistance, high &low temperature resistance, excellent elastic resilience, good strength. It can be cut into complex shape. Reinforced graphite gasket with inner &outer coating keeps all the excellent characteristics of itself, besides, it could be easily installed, disassembled, undamaged, meanwhile can prevent from medium corrosion, improve the pressure resistance.

2.Technical Data Sheet

|

Reinforced Material |

Pressure Resistance |

Temperature |

Elongation(%) |

Recovery(%) |

|

|

Oxidizing Environment |

Non-Oxidizing |

||||

|

CS Reinforce Sheet |

≥48 |

-10-450 |

-10-550 |

30-35 |

15-20 |

|

SS304,SS316 Reinforced Sheet |

≥48 |

-240-450 |

-200-600 |

30-35 |

15-30 |

|

SS304,SS316 Sheet |

≥48 |

-240-450 |

-200-600 |

30-40 |

10-15 |

|

Ss304, Mesh Sheet |

≥48 |

-240-450 |

-200-600 |

40-50 |

15-20 |

|

Reinforced Material |

Breathable (cm3/min) |

Leakage |

Seal Constant |

||

|

N2 m1/hr |

Bumming oil A |

“M” |

“Y” |

||

|

CS Reinforce Sheet |

<=0.8 |

30 |

<0.5 |

3.0 |

9000 |

|

SS304,SS316 Reinforced Sheet |

<=0.8 |

60 |

<0.5 |

2.5 |

4000 |

|

SS304,SS316 Sheet |

<=0.4 |

35 |

<0.5 |

2.0 |

900 |

|

SS304, Mesh Sheet |

≥1.0 |

70 |

<0.5 |

3.0 |

5000 |

Product detail pictures:

Related Product Guide:

A Look at the Molded Gasket

Comparison of O-Ring Materials

New Fashion Design for Reinforced Flexible Graphite Gasket Wholesale to Iran, The product will supply to all over the world, such as: , , ,

Packing Machine for Grain

Very compact and versatile machine,usable for any kind of cereals. ( Rice, Polenta, semolina).Bag magazine with a capacity of 400 bags. One single filling station with volumetric dosing. Vibrating table to compact the product, trimming of the exceeding paper. Folding and closing system through hot melt. The date is printed on the top side of the bag through a stamp with dating figures of 8mm height.Capacity 1200 bags/hour. The semi-automatic collective packer can be replaced by an automatic or semi-automatic polyethylen shrinkage system. This machine is controlled by PLC. All pneumatic parts according to ISO-norm. Changing the bag size does not need more than ten minutes. Very simple handling and maintenance mark this machine.

Site: https://www.ampacking.it

Mail: info@ampacking.it