Best quality and factory Tellerette Packing Ring for Costa rica Manufacturers

Best quality and factory Tellerette Packing Ring for Costa rica Manufacturers Detail:

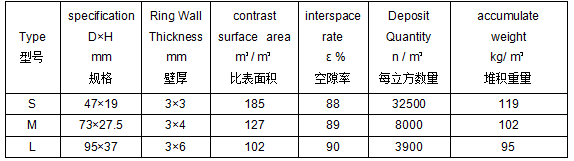

Material: PE, PP, RPP, PVC, CPVC and PVDF. Tellerette Packing Rings have features such as high void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific weight, high mass transfer efficiency, etc., and the application temperature in media ranges from 60℃ to 150 ℃.For these reasons, them are widely used in the packing towers in petroleum industry, chemical industry, alkali-Chloride industry, coal gas industry and environmental protection, etc.

Technical Data Sheet

Product detail pictures:

Related Product Guide:

What Is A PTFE Ring Gasket?

Comparison of O-Ring Materials

Best quality and factory Tellerette Packing Ring for Costa rica Manufacturers, The product will supply to all over the world, such as: , , ,

Introduction to the roll forming process.

(Hot Rolling: https://youtu.be/AuuP8L-WppI)

Steel Master Programme

The Master’s Programme in Metal Forming and Surface Technology is open to students with different backgrounds in materials, processes and applications. The programme is designed for students who are interested in continuing to doctoral studies and/or working as project leaders in industrial R&D within the steel industry or in various manufacturing industries.

The Programme has a strong focus on materials, advanced forming processes, surface technology, modelling and simulations, which includes sheet metal forming, the role of the materials in plastic forming operations, micro-structure developments and tribology in metal forming processes.

Watch more from Dalarna University on https://www.youtube.com/dalarnauniversity

or download on https://itunes.du.se