Wholesale Dealers of Pall Ring to Frankfurt Factory

Wholesale Dealers of Pall Ring to Frankfurt Factory Detail:

Pall Ring has features of low pressure drop, great flux, high efficiency.

Material: Stainless steel, carbon steel, aluminum, bronze, 304L, 316L, and other alloy, carbon seep aluminium.Strengthen polypropylene, strengthen nylon6, strengthen nylon66, strengthening PBT can also be requested by user.

Application: Used in all kind of separation, absorb, dis-absorb plants, constant decompress plants, compounding ammonia plant, decarbonization plant, desulfuration plant,separation of ethylbenzene, separation of isooctane/ methylbenzene.

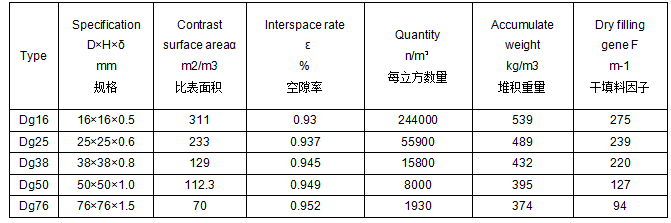

Technical Data Sheet

Product detail pictures:

Related Product Guide:

A Look at the Molded Gasket

What Is A PTFE Ring Gasket?

Wholesale Dealers of Pall Ring to Frankfurt Factory, The product will supply to all over the world, such as: , , ,

SEI LASER PackMaster CW

Laser flexibility for easy-open, window packaging, easy-ventilation, easy-breath in flexible packaging. System is designed for laser cutting, laser scoring, macro- and micro-perforation of single- or multi-layer flexible films.

Compatible materials include: paper, PE, PET, PP, nylon, PTFE and laminated films. Production markets for food & beverage, pet food, personal care and grocery products. Roll width of up to 1800 mm and process speed of up to 400 m/min.

It can be easily integrated into existing production lines. Very high precision in the material removal and macro/micro-perforation, repeat-ability of the process over time. Up to 400 m/min achievable in cutting, laser scoring and micro-perforation processes. The digital process enables immediate process changeover and a substantial reduction in time and costs (not possible in the case of “analogue” mechanical die cutters).

Printing, Packaging, Converting and Security RFID

European Equipment Supplier

Sold & Serviced by Matik, Inc.

Distributor in USA, Canada and Mexico

www.matik.com

This video shows the ATOM Flashcut dieless knife cutting machine nesting and cutting gasket sealing material.

Although this can be cut on any of the ATOM range of Flashcut’s, this is the general standard size bed for this application, giving the operator the ability to be unloading one half of the machine, relaod blank material and nest, whilst the second half of the machine is cutting. When the first zone is completed then the cutting beam will move over too the second half and restart, allowing the operator to be a continous production cycyle.